Article from Gavin Schneider

Have you ever walked a greenhouse crop with a skilled grower who could intuitively “read” a plant, as if the green leaves were lines on a page? This skill, which develops with time in the greenhouse, separates junior growers from head growers. The problem is that as greenhouses get bigger and the teams managing the crop get smaller, there is less opportunity to visually inspect all issues that come up. Visually inspecting plant leaves, stems, plant heads, and fruit quality gives important cues regarding plant health necessary to achieve high yields. With new technology, it's possible to read a plant remotely to get those same visual cues that indicate plant health.

Modern greenhouses are searching for innovative solutions to achieve higher yields, address labour shortages, and decrease crop loss from pests and diseases. There is a global shortage of highly trained growers, so management teams are turning to technology to fill in the gap. One proven solution is ecoation's forecasting platform. Specifically, the Virtual Walk displays data in a “Google Streetview” style version of the greenhouse for deep visibility into the crop. The feature uses a hardware package that includes a 360-degree camera, allowing growers and consultants to get the visual cues needed for effective crop management on a scale not possible on foot. When the OKO drives down a row of tomatoes, the camera sends an image of every square meter of the greenhouse to the ecoation digital platform. From here it is possible to see every single plant in the greenhouse from anywhere in the world.

This web app allows growers, scouts, IPM managers, greenhouse owners, and technical consultants to read how a tomato plant is growing without physically needing to be in the greenhouse. Each day that the OKO goes into a row, the data is refreshed. It’s also possible to go back in time to see exactly what a plant looked like days, weeks, or months ago. This digital record of crop growth enables a continuous record of crop work quality, fruit quality, and overall health of the crop.

Here is what you can see using Ecoation's 360 Degree Virtual Walk, broken down into core sections of a tomato plant:

Leaves

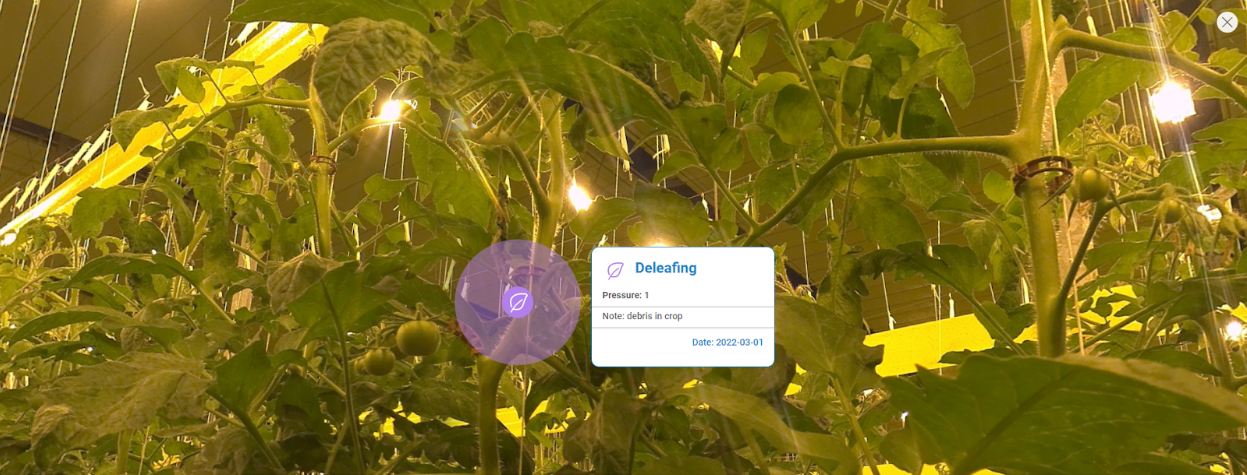

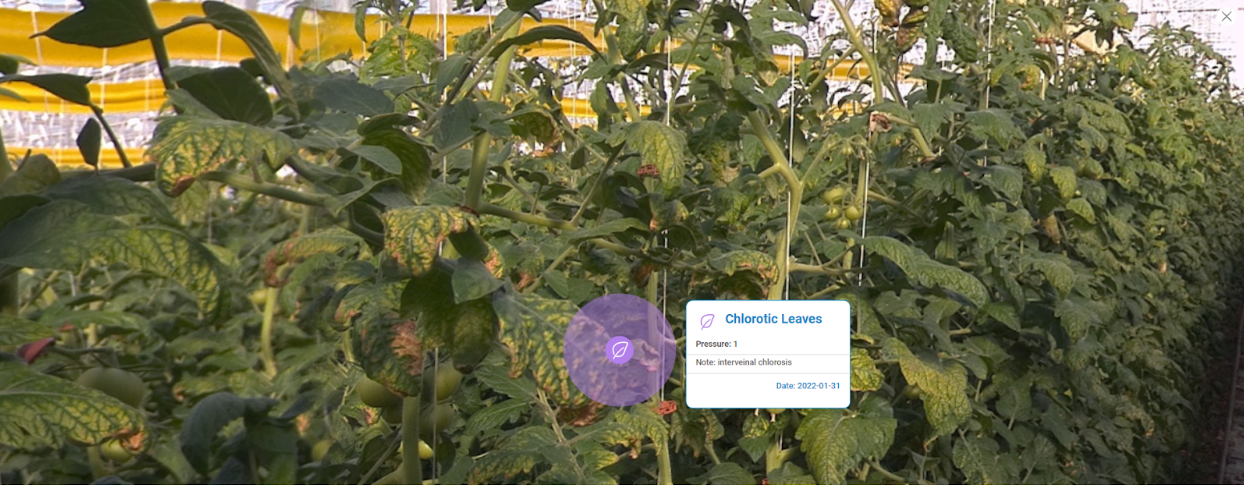

With leaves, shape, colour, curl, and size are all indicators of health. For example, if you see short leaves in the head, it indicates a lack of light, or that temperatures are too high in the greenhouse. Leaf edges rolling in indicates leaf curl, which can be caused by high temperatures, low humidity, or a lack of calcium. Leaf twisting can be caused by a range of factors, including pests, diseases, or nutrient deficiencies. Nutrient deficiencies are clear in the leaves, especially if you can associate nutrient mobility to mature or young leaf matter on the crop. Using the Virtual Walk, a grower is guided by smart alerting to problem areas. This way they can investigate the crop from root zone to head and get a good sense of what the leaves look like.

Plant Heads and Stems

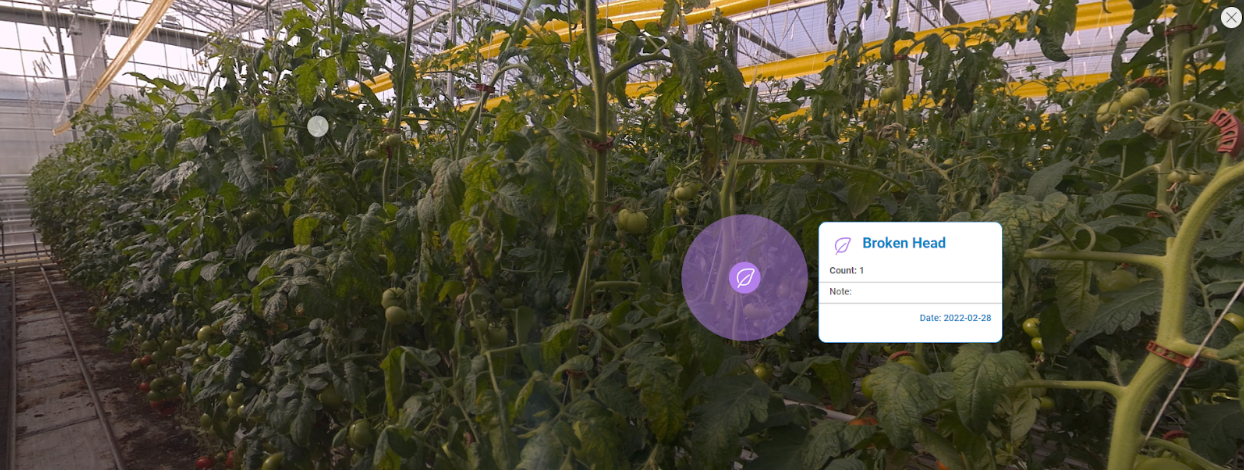

When it comes to information gathered by investigating plant heads, a good grower can steer the energy balance in the crop to achieve higher yields simply by becoming familiar with what a strong meristem looks like. For instance, a plant head that is too vegetative looks thick, while a too generative plant head looks thin and brittle. Signs of a too-generative plant also include flowers too close to the head. Grey plant heads reveal nutrient deficiencies, while chlorotic plant heads indicate a lack of iron. Purple heads in a tomato plant reveal that the night temperatures in the greenhouse are too cold. From the stems, it's possible to see signs of stem damage from de-leafing that cause an opening for diseases. Stems may be kinked, crooked, or show signs of damage. For example, nesidiocoris will cause chloritic rings on the stem that are visible to the grower. By driving the OKO at a height that captures the plant heads, a grower can very quickly spot-check several sections of the greenhouse in a matter of minutes. These cues should confirm that the growing strategy is steering the crop in the right direction.

Trusses and Flowers

During normal scouting height, the camera Measuring crop quality is important, and a key metric is observing truss and flower sets. Long, straight flower trusses reveal that there is enough light and that temperatures are too high in the greenhouse. A long straight flower truss can cause kinks in the truss, which can lead to reduced yield. On the other hand, a good flower truss looks like an arc, and the angle of the truss should be between 45 and 60 degrees. A pale flower colour indicates that relative humidity is too high in the early morning. While pollination is difficult to investigate remotely, flowers can be easily zoomed into and checked in detail from the ecoation web app. Flower health eventually turns into yield, and keeping a close eye on flower setting is an essential skill for an advanced tomato grower.

Pests and Diseases

The Ecoation 360 Degree Virtual Walk can also provide valuable insights into pest and disease management that impact plant health. While the camera is not a replacement for a scout, the camera is loaded with advanced virtual models. These run on the device and can indicate plant health and stress related to signs and symptoms of a pest or disease outbreak. The models point a grower to areas of the crop that need further investigation. Visible symptoms of pests and diseases in tomato plants can be spotted from the Virtual Walk, including powdery mildew, as well as damage caused by aphids, spider mites, thrips, and more. Early detection and treatment of these issues can lead to increased yields and reduced losses. It's common for an IPM Manager to follow up on specific locations that a scout identifies as problematic. With the ecoation platform, the IPM Manager is alerted in real-time. They can then use the webapp to quickly verify the pest and disease issue that the scout identified in the greenhouse.

Fruits

The fruit of a tomato plant can also provide valuable insights into steering strategy and management effectiveness. While using the OKO during the fruit forecasting process, the camera is centred along the generative section of the tomato plant, counting fruit and classifying ripeness. This automated, machine learning-enabled process turns fruit counts into a yield forecast. However, it doesn’t give the same insights into fruit quality that a trained eye can decipher. If the rest of the crop is managed well — that photosynthesis is maximized and the plant is actively transporting sugars throughout the day — the result will be beautiful, consistent, well-coloured fruit. Fruit splitting and surface cracks are often caused by inconsistent watering, which is easily spotted in the Virtual Walk. Purple coloration in the fruit is due to high light intensity, which can be verified by looking at the lower PAR measurements that the OKO collects. Blossom end rot, a symptom of calcium imbalance and incorrect watering, reveals itself in the fruit. A spot check of low-yielding rows can reveal that fruit setting is poorly managed and that broader issues are happening with the fruit development. Finally, it is possible to check the rows in the virtual walk before and after harvest to assess harvesting efficiency. (Are all the red fruit picked? Is there any fruit on the ground? etc.) As tomato greenhouses get bigger, a skilled grower can easily extend their acreage by using the virtual walk to see more fruit, all from the comfort of their head office.

Conclusion

In conclusion, the Ecoation 360 Degree Virtual Walk is a valuable tool for modern greenhouse growers. It allows them to see more plants in less time with less wasted energy. Leaf heath, plant heads, stems, pest damage, and fruit quality can all be spot checked remotely using this tool. The ability to view every tomato in a large greenhouse, coupled with the expertise of consultants who can log in virtually from anywhere in the world, provides growers with the insights they need to optimize their entire operation. This is particularly beneficial in today's labour market, where labour shortages for highly trained growers are becoming increasingly common. These shortages are forcing greenhouses to find new technology solutions to be able to grow more hectares with fewer people. By harnessing the power of digital agriculture and agronomy, growers can use fewer resources to produce more food.